Who We Are?

ONY Co., Ltd. is specialized in providing both service and equipment in assisting the customer who need to initiate into the Fasteners manufacturing or for any potential fastener producer to expand their current equipment or any more complicated functional equipment.

The highest principle of ONY company is to provide the best quality equipment to meet customers’ requirement to maximize the production volume.

The philosophy is to create win-win situation for both parties so that the mutually corporation could last forever.

from Sales Manager / Young Yang

Obviously, we sincerely hope any customers who corporate with us would be satisfied with our service.

Contact Us Anytime!

Young Yang

Foreign Dept. Sales Manager,

Cell: +886-970-535-046

Tel: +886-6-267-6086

Fax: +886-6-267-6089

Address: No.247, ChongXue Rd., East Dist., Tainan City 70156, Taiwan.

Email: young@ony.tw

What We Provide?

1. Wire drawing machine.

This is use to draw the wire diameter to customer’s ideal dimension.

2. Phosphate wire lubricate equipment.

This is the lubricant coating on the wire.

3. Cold forge machine including Bolt, nut & special parts forming machine.

This is really depends upon the requirements of the parts and we provide many different kind of forming machines and we our experience we could evaluate the products to work it out the most suitable machine with reasonable cost to complete the job. More over, we do provide not only regular cold forming machines, but also special heading machines such as 1 die 2 blow, 2 die 4 blow machines also for some special application like reheading machine and many more options.

4. Press machine.

Some parts are suitable to be manufactured with stamping other than cold forge.

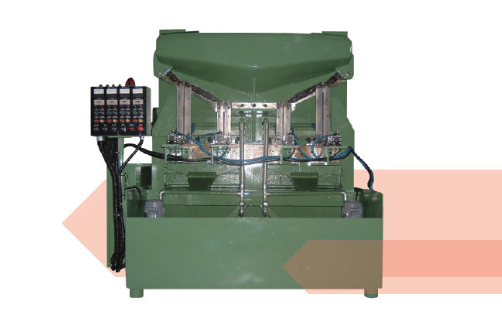

5. S.P.M. (Special purpose machine)

Some complicated parts require 2nd operation after the 1st cold forming process and our team could assist customers to develop such special purpose machine to meet individually needs.

6. Flat die or circular die thread rolling machines

Depends upon different bolts or screws and we could offer suitable kind of rolling machine to do the job.

7. Nut tapping machine.

Nut tapping machine.

8. Surface hardening continuous type heat treatment furnace.

Surface hardening continuous type heat treatment furnace.

9. Continuous type electro plating equipment.

Continuous type electro plating equipment.

10. Optical sorting machine.

This is used to inspect the products to minimize the PPM to single digits to meet customer’s request.

11. Product packing machine.

This is used to pack the products automatically. So that encouraging on saving the labour waste.