5 Station / 6 Station Short Part Former PF-Series

Specification

| SPECIFICATION MODEL | PF-8B5S | PF-8B6S | PF-11B5S | PF-13B6S | PF-15B5S |

| FORGING STATION | 5 | 6 | 5 | 6 | 5 |

| CUT-OFF DIA(MAX)(MM) | 8 | 11 | 11 | 15 | 15 |

| CUT-OFF LENGTH(MAX)(MM) | 12 | 18 | 18 | 35 | 35 |

| CUTTER TYPE | OPEN TYPE | CLOSE TYPE | CLOSE TYPE | CLOSE TYPE | CLOSE TYPE |

| TRANSFER TYPE | ROTATING TYPE | ROTATING TYPE | ROTATING TYPE | ROTATING TYPE | ROTATING TYPE |

| K.O LENGTH (MM) | 16 | 30 | 30 | 42 | 42 |

| P.K.O(DIA x LENGTH) (MM) | 8 | 8 | 10 | 20 | 20 |

| CUT-OFF QUILL(DIA x LENGTH)(MM) | 36×60 | 35×56 | 35×56 | 46×80 | 46×80 |

| MAIN DIE(DIA x LENGTH)(MM) | 37×42 | 37×70 | 45×70 | 55×70 | 65×90 |

| CENTER DISTANCE BETWEEN DIES | 37 | 37 | 45 | 55 | 65 |

| PUNCH HOLE(DIA x LENGTH)(MM) | 25×67 | 25×67 | 30×80 | 40×90 | 40×90 |

| RAM STROKE(MM) | 75 | 90 | 90 | 185 | 185 |

| FORGING POWER(TON) | 30 | 60 | 60 | 100 | 100 |

| OUTPUT PCS/MINUTE(MAX) | 200 | 170 | 170 | 150 | 150 |

| MAIN MOTOR(HP) | 15 | 20 | 20 | 30 | 30 |

| APPROX.WT(KG) | 6000 | 8000 | 8000 | 14000 | 14000 |

| SPECIFICATION MODEL | PF-17B6S | PF-19B5S | PF-21B6S | PF-25B5S | PF-28B6S |

| FORGING STATION | 6 | 5 | 6 | 5 | 6 |

| CUT-OFF DIA(MAX)(MM) | 17 | 17 | 21 | 21 | 28 |

| CUT-OFF LENGTH(MAX)(MM) | 50 | 50 | 70 | 70 | 100 |

| CUTTER TYPE | CLOSE TYPE | CLOSE TYPE | CLOSE TYPE | CLOSE TYPE | CLOSE TYPE |

| TRANSFER TYPE | ROTATING TYPE | ROTATING TYPE | ROTATING TYPE | ROTATING TYPE | ROTATING TYPE |

| K.O LENGTH (MM) | 70 | 70 | 80 | 80 | 120 |

| P.K.O(DIA x LENGTH) (MM) | 25 | 25 | 30 | 30 | 35 |

| CUT-OFF QUILL(DIA x LENGTH)(MM) | 80×90 | 80×90 | 70×75 | 70×75 | 95×100 |

| MAIN DIE(DIA x LENGTH)(MM) | 72×72 | 80×72 | 93×110 | 114×110 | 120×160 |

| CENTER DISTANCE BETWEEN DIES | 72 | 80 | 93 | 114 | 126 |

| PUNCH HOLE(DIA x LENGTH)(MM) | 42×120 | 48×120 | 60×120 | 75×122 | 75×155 |

| RAM STROKE(MM) | 200 | 200 | 240 | 240 | 250 |

| FORGING POWER(TON) | 165 | 165 | 250 | 250 | 460 |

| OUTPUT PCS/MINUTE(MAX) | 100 | 100 | 90 | 90 | 70 |

| MAIN MOTOR(HP) | 50 | 50 | 100 | 100 | 150 |

| APPROX.WT(KG) | 23000 | 23000 | 42000 | 42000 | 66000 |

| SPECIFICATION MODEL | PF-36B5S | PF-36B6S | PF-45B5S | PF-45B6S | PF-55B5S |

| FORGING STATION | 5 | 6 | 5 | 6 | 5 |

| CUT-OFF DIA(MAX)(MM) | 28 | 36 | 36 | 45 | 45 |

| CUT-OFF LENGTH(MAX)(MM) | 100 | 150 | 150 | 150 | 150 |

| CUTTER TYPE | CLOSE TYPE | CLOSE TYPE | CLOSE TYPE | CLOSE TYPE | CLOSE TYPE |

| TRANSFER TYPE | ROTATING TYPE | ROTATING TYPE | ROTATING TYPE | ROTATING TYPE | ROTATING TYPE |

| K.O LENGTH (MM) | 120 | 120 | 120 | 130 | 130 |

| P.K.O(DIA x LENGTH) (MM) | 35 | 40 | 40 | 50 | 50 |

| CUT-OFF QUILL(DIA x LENGTH)(MM) | 95×100 | 110×155 | 110×155 | 132×155 | 132×155 |

| MAIN DIE(DIA x LENGTH)(MM) | 156×160 | 156×220 | 195×220 | 178×330 | 220×330 |

| CENTER DISTANCE BETWEEN DIES | 156 | 156 | 195 | 195 | 235 |

| PUNCH HOLE(DIA x LENGTH)(MM) | 110×155 | 110×220 | 120×220 | 120×312 | 135×312 |

| RAM STROKE(MM) | 250 | 260 | 260 | 260 | 260 |

| FORGING POWER(TON) | 460 | 600 | 600 | 900 | 900 |

| OUTPUT PCS/MINUTE(MAX) | 70 | 55 | 55 | 45 | 45 |

| MAIN MOTOR(HP) | 150 | 175 | 175 | 300 | 300 |

| APPROX.WT(KG) | 66000 | 105000 | 105000 | 180000 | 180000 |

* WE RESERVE THE RIGHT TO CHANGE THE DESIGNS & SPECIFICATIONS WITHOUT NOTICE.

Features

A. OVER ARM MAIN SLIDE:

All PF series models use an Over Arm main slide which increases the stability during formation process, and the P.K.O. system that allows more varieties of products to be produced.

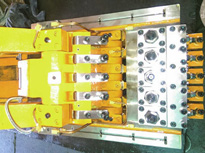

B. TRANSFER FEEDING MECHINISM:

The transfer mechanism includes the I-style pneumatic clamp, nut former style rotating transfer mechanism, and the fingers are capable of opening and closing; these allow larger head size products to be produced. The rotating transfer stations can also be adjusted to rotate 180 degrees or have no

C. CUTTER MECHANISM:

The round closed cutter mechanism allows a smoother cut on the material surface.

D. TRANSFER STATION TRANSMISSION:

Transfer station’s transmission has moved to the cutter’s side, allowing the operator to be closer to the machine to make operations more convenient.

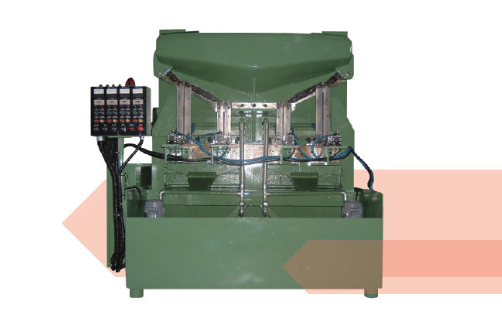

PF-45B6S

PF-15B5S

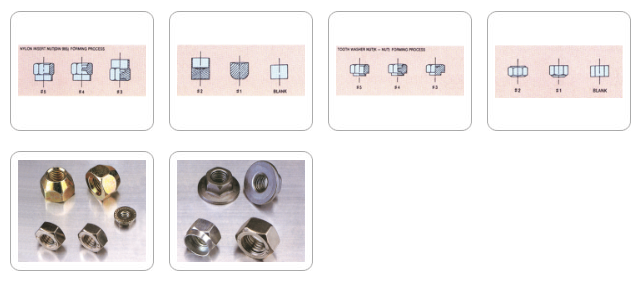

Product Samples