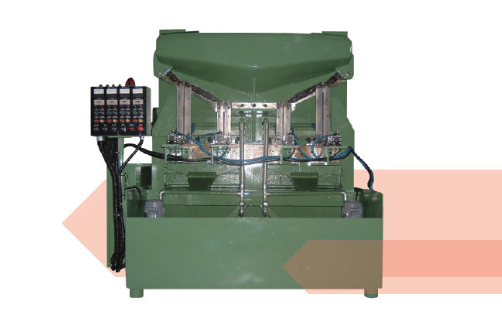

5 Station Bolt Former BF-Series

Specification

| SPECIFICATION MODEL | BF-10B5S | BF-13B5S | BF-19B5S | BF-24B5S |

| FORGING STATION | 5 | 5 | 5 | 5 |

| CUT-OFF DIA(MAX)(MM) | 12 | 16 | 18 | 23 |

| CUT-OFF LENGTH(MAX)(MM) | 105 | 130 | 190 | 205 |

| KICK-OUT LENGTH(MAX)(MM) | 80 | 120 | 150 | 190 |

| PUNCH KICK-OUT LENGTH (MM) | 20 | 20,35,50 | 35 | 40 |

| CUT-OFF QUILL (DIA x LENGTH)(MM) | 35×56 | 46×80 | 60X100 | 80×100 |

| MAIN DIE (DIA x LENGTH)(MM) | 50×95 | 75×130 | 90×170 | 115×205 |

| CENTER DISTANCE BETWEEN DIES(MM) | 60 | 87 | 114 | 126 |

| PUNCH HOLE (DIA x LENGTH)(MM) | 40×95 | 60×120 | 60×122 | 90×164 |

| RAM STROKE(MM) | 160 | 190 | 260 | 320 |

| PRODUCTS | 5/16”(M8) | 3/8”(M10) | 1/2”(M12) | 5/8”(M16) |

| FORGING POWER (TON) | 60 | 90 | 160 | 200 |

| OUTPUT (PCS/MINUTE)(MAX) | 150 | 130 | 110 | 90 |

| MAIN MOTOR(HP) | 20 | 30 | 50 | 100 |

| LUBRICATION MOTOR(HP) | 1 | 1 | 2 | 2 |

| COOLING MOTOR(HP) | 1/2 | 1 | 1 | 1 |

| LUBRICATION(L) | 200 | 200 | 300 | 500 |

| COOLANT(L) | 300 | 300 | 400 | 600 |

| APPROX.WT(KG) | 13000 | 18000 | 42000 | 58000 |

| SPECIFICATION MODEL | BF-30B5S | BF-33B5S | BF-36B5S | BF-41B5S |

| FORGING STATION | 5 | 5 | 5 | 5 |

| CUT-OFF DIA(MAX)(MM) | 30 | 29 | 34 | 38 |

| CUT-OFF LENGTH(MAX)(MM) | 270 | 270 | 330 | 410 |

| KICK-OUT LENGTH(MAX)(MM) | 220 | 220 | 280 | 370 |

| PUNCH KICK-OUT LENGTH (MM) | 45 | 50 | 55 | 60 |

| CUT-OFF QUILL (DIA x LENGTH)(MM) | 90×140 | 100×120 | 105X140 | 115×155 |

| MAIN DIE (DIA x LENGTH)(MM) | 125×240 | 145×240 | 160×300 | 175×400 |

| CENTER DISTANCE BETWEEN DIES(MM) | 138 | 156 | 174 | 195 |

| PUNCH HOLE (DIA x LENGTH)(MM) | 90×220 | 110×250 | 120×290 | 130×290 |

| RAM STROKE(MM) | 360 | 360 | 440 | 520 |

| PRODUCTS | 3/4”(M20) | 1”(M24) | 1 1/8”(M27) | 1 1/4”(M30) |

| FORGING POWER (TON) | 300 | 440 | 500 | 600 |

| OUTPUT (PCS/MINUTE)(MAX) | 70 | 70 | 60 | 50 |

| MAIN MOTOR(HP) | 125 | 150 | 175 | 200 |

| LUBRICATION MOTOR(HP) | 2 | 2×2 | 2×2 | 2×2 |

| COOLING MOTOR(HP) | 1 | 1 | 1 | 1 |

| LUBRICATION(L) | 600 | 800 | 950 | 1000 |

| COOLANT(L) | 700 | 800 | 950 | 950 |

| APPROX.WT(KG) | 80000 | 100000 | 130000 | 180000 |

* WE RESERVE THE RIGHT TO CHANGE THE DESIGNS & SPECIFICATIONS WITHOUT NOTICE.

Features

A. New PATENT AIR CLUTCH/BRAKE SYSTEM WITH INVERTER:

FEEDING:

The new patented air clutch/brake system can save more energy. It is more easily maintained and avoids the oil gas. With the inverter, it can reduce production cost effectively.

B. HORIZONTAL – TYPE K.O

K.O main rod and K.O. force are in the same force center line. (designed for long stroke model)

C. MAIN SHIM-PLATED SLIDER:

The main shim-plated slider using self-lubricant copper can maintain the lubrication of the main slider and keep the life and accuracy of the slider.

D. I-TYPE CHUCK FINGER:

With pneumatic cylinder device to fasten the blank, which is simple & quick to adjust the transfer chuck fingers into the die center position.