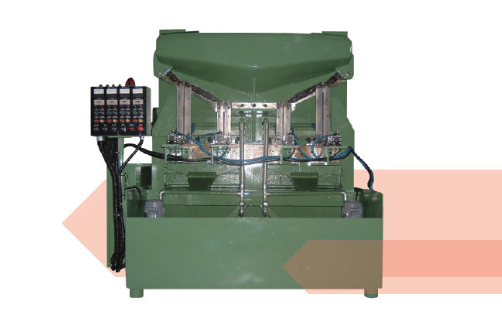

5 Station Nut Former NF-Series

Specification

| SPECIFICATION MODEL | NF-8B5S | NF-10B5S | NF-13B5S | NF-14B5S | NF-17B5S | |

| FORGING STATION | 5 | 5 | 5 | 5 | 5 | |

| CUT-OFF DIA(MAX) (MM) | 8 | 10 | 13 | 14 | 17 | |

| CUT-OFF LENGTH(MAX) (MM) | 6 | 8 | 10 | 12 | 13 | |

| KICK-OUT LENGTH(MAX)(MM) | 10 | 13 | 15 | 18 | 20 | |

| PUNCH KICK-OUTLENGTH(MAX)(MM) | ——- | ——- | ——- | ——- | ——- | |

| CUT-OFF QUILL(DIA x LENGTH) (MM) | 37×45 | 45×55 | 55×65 | 62×75 | 72×80 | |

| MAIN DIE(DIA x LENGTH)(MM) | 37×42 | 45×46 | 55×50 | 62×60 | 72×65 | |

| CENTER DISTANCEBETWEEN DIES(MM) | 37 | 45 | 55 | 62 | 72 | |

| PUNCH HOLE(DIA x LENGTH) (MM) | 25×67 | 30×83 | 37×89 | 40×100 | 42×100 | |

| RAM STROKE(MM) | 60 | 70 | 70 | 80 | 80 | |

| FORGING POWER(TON) | 26 | 40 | 75 | 90 | 110 | |

| PRODUCTS | (INCH) | #8 | #10,1/4″ | #12,5/16″ | 3/8″ | 3/8″ |

| (M/M) | M5 | M6 | M8 | M8 | M10 | |

| OUTPUT PCS/MINUTE(MAX) | 360 | 300 | 250 | 230 | 220 | |

| MAIN MOTOR(HP) | 15 | 15 | 20 | 30 | 30 | |

| LUBRICATION MOTOR(HP) | 1 | 1 | 1 | 1 | 1.5 | |

| COOLING MOTOR(HP) | 1 | 1 | 1 | 1 | 1.5 | |

| LUBRICATION(L) | 150 | 150 | 180 | 190 | 190 | |

| COOLANT(L) | 200 | 200 | 220 | 220 | 220 | |

| APPROX.WT(KG) | 4000 | 5500 | 9000 | 10500 | 12000 | |

| SPECIFICATION MODEL | NF-19B5S | NF-24B5S | NF-28B5S | NF-32B5S | NF-36B5S | |

| FORGING STATION | 5 | 5 | 5 | 5 | 5 | |

| CUT-OFF DIA(MAX)(MM) | 19 | 24 | 28 | 32 | 36 | |

| CUT-OFF LENGTH(MAX)(MM) | 14 | 18 | 27 | 28 | 30 | |

| KICK-OUT LENGTH(MAX)(MM) | 25 | 30 | 35 | 40 | 45 | |

| PUNCH KICK-OUTLENGTH(MAX)(MM) | ——- | ——- | ——- | ——- | ——- | |

| CUT-OFF QUILL(DIA x LENGTH)(MM) | 80×90 | 100×110 | 120×130 | 140×150 | 160×170 | |

| MAIN DIE(DIA x LENGTH) (MM) | 80×70 | 100×90 | 120×105 | 156×120 | 160×135 | |

| CENTER DISTANCEBETWEEN DIES(MM) | 80 | 100 | 120 | 140 | 160 | |

| PUNCH HOLE(DIA x LENGTH) (MM) | 48×120 | 60×135 | 72×160 | 84×180 | 96×220 | |

| RAM STROKE(MM) | 90 | 120 | 140 | 160 | 180 | |

| FORGING POWER(TON) | 140 | 220 | 280 | 400 | 500 | |

| PRODUCTS | (INCH) | 1/2″ | 5/8″ | 3/4″ | 7/8″ | 1″ |

| (M/M) | M12 | M16 | M18 | M22 | M24 | |

| OUTPUT PCS/MINUTE(MAX) | 190 | 145 | 130 | 110 | 100 | |

| MAIN MOTOR(HP) | 40 | 50 | 75 | 100 | 125 | |

| LUBRICATION MOTOR(HP) | 2 | 2 | 3 | 3 | 3 | |

| COOLING MOTOR(HP) | 2 | 2 | 2 | 3 | 3 | |

| LUBRICATION(L) | 250 | 350 | 400 | 900 | 1000 | |

| COOLANT(L) | 350 | 450 | 500 | 1000 | 1100 | |

| APPROX.WT(KG) | 15500 | 22000 | 36000 | 52000 | 80000 | |

* WE RESERVE THE RIGHT TO CHANGE THE DESIGNS & SPECIFICATIONS WITHOUT NOTICE.

Features

A. NF-32B5S

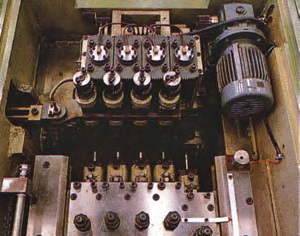

CUT-OFF & FEEDING MECHANISM:

The reciprocal motion in cutting is guided by S-Cam cut off & air cylinder. According to customer’s need, feed length can be adjusted by servo motor. (Optional)

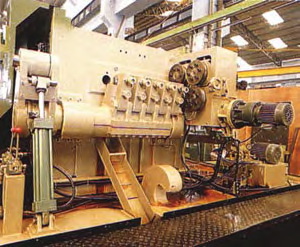

B. NF-32B5S

FEEDING & KICK-OFF MECHANISM:With hydraulic cylinder helps, K.O system becomes more easily in the change of die. Forward or backward of feed by servo motor.(under NF24B is optional)

C. NF-32B5S

CUT-OFF & TRANSFER MECHANISM:

Rotation type transfer is permit to setup the finger turning180° or not. The motion between the cut-off & transfer is used in synchro running. And also, Cut-Off with open knife mechanism.

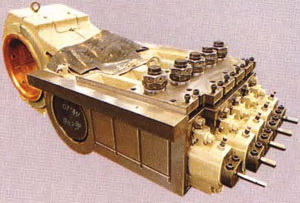

D. NF-32B5S

MAIN SLIDE:

Main slide is facile to adjust punch position (up to down, left to right, front to rear) which is firm & accurate maintenance for durable utility.

Product Samples