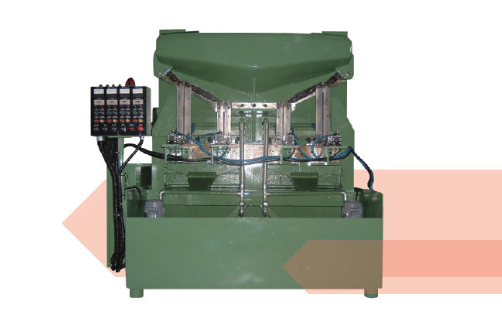

5 Station Special Part Former BP-Series

Specification

| SPECIFICATION MODEL | BP-10B5S | BP-13B5S | BP-19B5S | BP-24B5S |

| FORGING STATION | 5 | 5 | 5 | 5 |

| CUT-OFF DIA (MAX) (MM) | 12 | 16 | 18 | 23 |

| CUT-OFF LENGTH (MAX) (MM) | 105 | 130 | 190 | 205 |

| KICK-OUT LENGTH (MAX) (MM) | 80(40) | 120(40) | 150(50) | 190(60) |

| PUNCH KICK-OUT LENGTH (MAX) (MM) | 20 | 20.35.50 | 35 | 40 |

| CUT-OFF QUILL (DIA x LENGTH) (MM) | 35×56 | 46×80 | 60×100 | 80×100 |

| MAIN DIE (DIA x LENGTH) (MM) | 50×95 | 75×130 | 90×170 | 115×205 |

| CENTER DISTANCE BETWEEN DIES (MM) | 60 | 87 | 114 | 126 |

| PUNCH HOLE (DIA x LENGTH) (MM) | 40×95 | 60×120 | 60×122 | 90×164 |

| RAM STROKE (MM) | 160 | 190 | 260 | 320 |

| FORGING POWER (TON) | 60 | 90 | 160 | 200 |

| OUTPUT PCS/MINUTE (MAX) | 150 | 130 | 110 | 90 |

| MAIN MOTOR (HP) | 20 | 30 | 50 | 100 |

| LUBRICATION MOTOR (HP) | 1 | 1 | 2 | 2 |

| COOLING MOTOR (HP) | 1/2 | 1 | 1 | 1 |

| LUBRICATION (L) | 200 | 200 | 300 | 500 |

| COOLANT (L) | 300 | 300 | 400 | 600 |

| APPROX.WT (KG) | 13000 | 18000 | 42000 | 58000 |

| SPECIFICATION MODEL | BP-30B5S | BP-33B5S | BP-36B5S | BP-41B5S |

| FORGING STATION | 5 | 5 | 5 | 5 |

| CUT-OFF DIA (MAX) (MM) | 30 | 29 | 34 | 38 |

| CUT-OFF LENGTH (MAX) (MM) | 270 | 270 | 330 | 410 |

| KICK-OUT LENGTH (MAX) (MM) | 220(80) | 220(80) | 280(100) | 370(170) |

| PUNCH KICK-OUT LENGTH (MAX) (MM) | 45 | 50 | 55 | 60 |

| CUT-OFF QUILL (DIA x LENGTH) (MM) | 95×120 | 100×120 | 105×140 | 115×155 |

| MAIN DIE (DIA x LENGTH) (MM) | 125×240 | 145×240 | 160×300 | 175×400 |

| CENTER DISTANCE BETWEEN DIES (MM) | 138 | 156 | 174 | 195 |

| PUNCH HOLE (DIA x LENGTH) (MM) | 90×220 | 110×250 | 120×290 | 130×290 |

| RAM STROKE (MM) | 360 | 360 | 440 | 520 |

| FORGING POWER (TON) | 300 | 440 | 500 | 600 |

| OUTPUT PCS/MINUTE (MAX) | 70 | 70 | 60 | 50 |

| MAIN MOTOR (HP) | 125 | 150 | 175 | 175 |

| LUBRICATION MOTOR (HP) | 2 | 2 x 2 | 2 x 2 | 2 x 2 |

| COOLING MOTOR (HP) | 1 | 1 | 1 | 1 |

| LUBRICATION (L) | 600 | 800 | 950 | 1000 |

| COOLANT (L) | 700 | 800 | 950 | 950 |

| APPROX.WT (KG) | 80000 | 100000 | 130000 | 180000 |

* WE RESERVE THE RIGHT TO CHANGE THE DESIGNS & SPECIFICATIONS WITHOUT NOTICE.

Features

A. BP-19B5S

TRANSFER CHUCK FINGER MECHANISM:

2 types of transfer can be changed independently. (translation or rotation finger clamping motion)

B. BP-19B5S

AIR CLUTCH / BRAKE SYSTEM:

Air clutch and air brake both available according to customer’s need. (Optional)

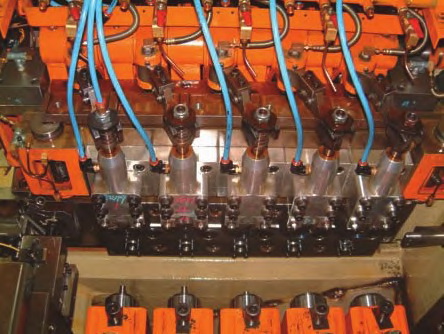

C. BP-13B5S

P.K.O MECHANISM:

According to customer’s need, P.K.O. stroke can be individually adjusted & simply setting P.K.O. cam in the 3 position; tools change can be done in short time.

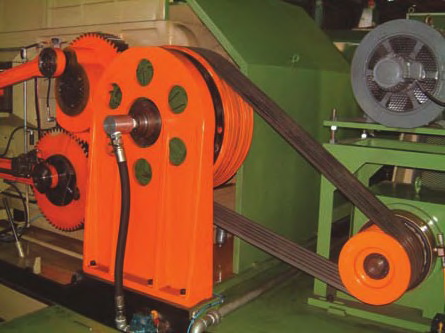

D. BP-13B5S

MAIN CRANKSHAFT & BACKSHAFT: Power ring assures firmly connected between crankshaft and flywheel, allow safety slipping to prevent any damage when accident happen. Additional Backshaft device for large-sized former; with protection against possible overloads system in gear motion.

E. BP-19B5S

TRANSFER HOUSING ADJ SYSTEM:

The transfer housing up/down adjustment by lever way to control easily. Some of the model with motor adjusting device, which is more easy to operate.

F. BP-19B5S

FEEDING & CUT-OFF MECHANISM:

By 4 wheel feeding roller-guide to feed the material smoothly into the machine. S-Cam cut off is the same as the center line of main shaft, can bear more force.

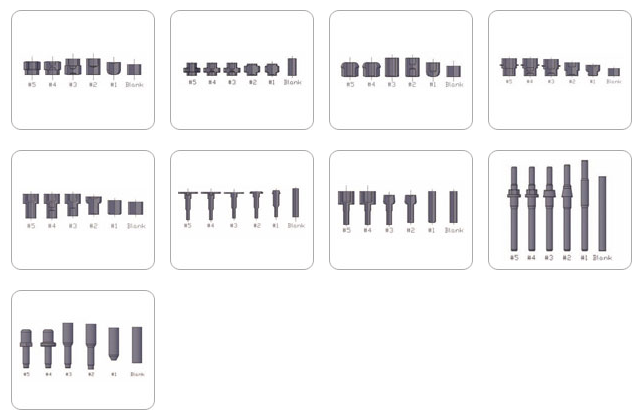

Product Samples