6 Station Special Part Former BP-Series

Specification

| SPECIFICATION MODEL | BP-10B6S | BP-11B6S | BP-13B6S | BP-19B6S |

| FORGING STATION | 6 | 6 | 6 | 6 |

| NO. OF FINGER’S | 6 | 6 | 7 | 7 |

| CUT-OFF DIA (MAX) (MM) | 12 | 16 | 16 | 23 |

| CUT-OFF LENGTH (MIX) (MAX) (MM) | 105 | 130 | 15/135 | 20/165 |

| KICK-OUT LENGTH (MIX) (MAX) (MM) | 80(40) | 120(40) | 120/40 | 150/50 |

| PUNCH KICK-OUT LENGTH (MAX) (MM) | 20 | 30 | 20.35.50 | 20.35.50 |

| CUT-OFF QUILL (DIA x LENGTH) (MM) | 35X56 | 46X80 | 46×80 | 68×100 |

| MAIN DIE (DIA x LENGTH) (MM) | 50×95 | 60×130 | 75x130L | 100x165L |

| CENTER DISTANCE BETWEEN DIES(MM) | 60 | 75 | 87 | 114 |

| PUNCH HOLE (DIA x LENGTH) (MM) | 40×95 | 40×111 | 60x120L | 75x142L |

| RAM STROKE (MM) | 160 | 190 | 190 | 260 |

| FORGING POWER (TON) | 80 | 90 | 145 | 230 |

| OUTPUT PCS/MINUTE (MAX) | 180 | 130 | 120 | 90 |

| MAIN MOTOR (HP) | 30 | 30 | 40 | 75 |

| LUBRICATION MOTOR (HP) | 1 | 1 | 1 | 2 |

| COOLING MOTOR (HP) | 1/2 | 1 | 1 | 1 |

| LUBRICATION (L) | 200 | 200 | 200 | 800 |

| COOLANT (L) | 300 | 300 | 300 | 600 |

| APPROX.WT (KG) | 15000 | 18000 | 25000 | 52000 |

| SPECIFICATION MODEL | BP-24B6S | BP-30B6S | BP-33B6S | BP-36B6S |

| FORGING STATION | 6 | 6 | 6 | 6 |

| NO. OF FINGER’S | 7 | 7 | 7 | 7 |

| CUT-OFF DIA (MAX) (MM) | 30 | 34 | 38 | 41 |

| CUT-OFF LENGTH (MIX) (MAX) (MM) | 30/200 | 40/270 | 45/330 | 50/410 |

| KICK-OUT LENGTH (MIX) (MAX) (MM) | 160/80 | 220/80 | 280/100 | 370/170 |

| PUNCH KICK-OUT LENGTH (MAX) (MM) | 20.40.60 | 25.50.75 | 25.55.80 | 30.60.90 |

| CUT-OFF QUILL (DIA x LENGTH) (MM) | 95x120L | 100x120L | 105x140L | 115x155L |

| MAIN DIE (DIA x LENGTH) (MM) | 116x184L | 125x240L | 145x300L | 160x400L |

| CENTER DISTANCE BETWEEN DIES | 126 | 138 | 156 | 174 |

| PUNCH HOLE (DIA x LENGTH) (MM) | 95x176L | 100x220L | 110x250L | 120x290L |

| RAM STROKE (MM) | 320 | 360 | 440 | 520 |

| FORGING POWER (TON) | 320 | 440 | 500 | 600 |

| OUTPUT PCS/MINUTE (MAX) | 90 | 70 | 60 | 50 |

| MAIN MOTOR (HP) | 100 | 125 | 150 | 175 |

| LUBRICATION MOTOR (HP) | 2 | 2 | 2 x 2 | 2 x 2 |

| COOLING MOTOR (HP) | 1 | 1 | 1 | 1 |

| LUBRICATION (L) | 800 | 900 | 950 | 1000 |

| COOLANT (L) | 600 | 700 | 700 | 950 |

| APPROX.WT (KG) | 65000 | 100000 | 130000 | 180000 |

* WE RESERVE THE RIGHT TO CHANGE THE DESIGNS & SPECIFICATIONS WITHOUT NOTICE.

Features

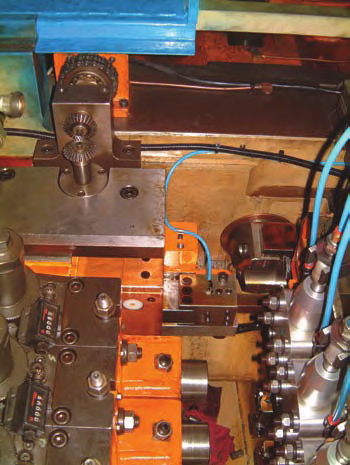

A. BP-19B6S

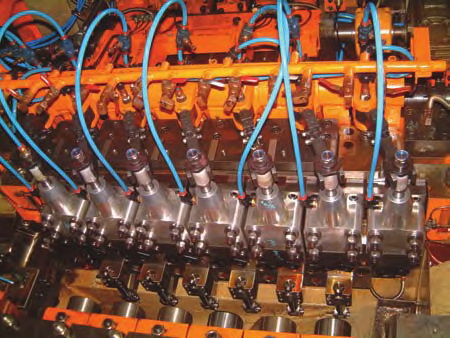

P.K.O MECHANISM:

Newly patented design; PKO stroke can be individually adjusted simply setting on each station, the P.K.O cam with 3 positions, tools change can be done in short time.

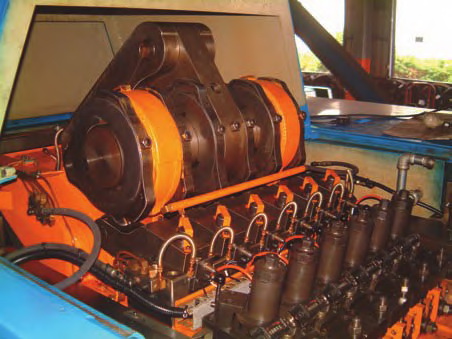

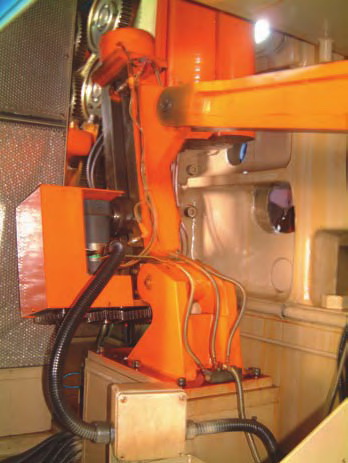

B. BP-19B6S

TRANSFER CHUCK FINGER MECHANISM:

I-TYPE transfer housing combine with Rotation type, the chuck finger enables to turn 180° or not. In this system, it can be used lifting type finger for large head parts produce.

C. BP-19B6S

KICK-OUT MECHANISM:

According to customer’s need, K.O. length position can be adjusted by hand wheel system or motor control.(Optional)

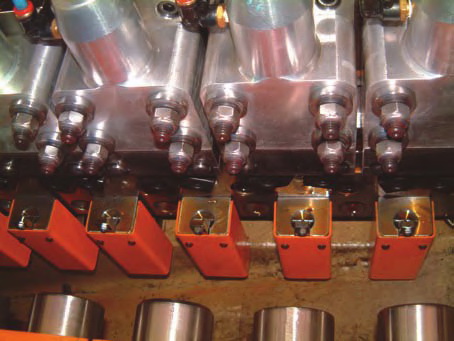

D. BP-19B6S

PFAS MECHANISM :

PFAS (Parts Forming Assist System) has been developed for secure transfer support of blanks like short shank parts which are difficult to chuck properly.

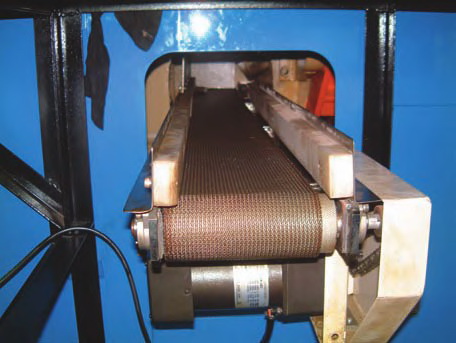

E. BP-19B6S

CONVEYOR:

Adding the 7th chuck finger to clamp the formed blank on specific conveyor, it prevent the damage in surface of the parts.

F. BP-19B6S

TRANSMISSION:

A-C main motor with transistor inverter, it helps to reach the production speed in the position which can reduce production costs.

G. BP-19B6S

FEED LENGTH ADJUSTING SYSTEM:

According to customer’s need, feed length can be adjusted by the servo motor adjusting system.(Optional)

H. BP-19B6S

STOPPER LENGTH MECHANISM:

According to customer’s need, stopper length can be adjusted by the servo motor system.(Optional)